FLANGES

A flange is forged or cast ring of metal designed to join two sections of a piping system or originate a piping system at a pressure vessel outlet, valve, or any other integral flanged assembly.

Flanges are joined to the piping system by threading or welding and are joined to each other with bolts. For example, every pressure vessel made has at least one flanged outlet. This outlet has a predetermined bolt circle and several holes. Flanges are designed and made to match the bolt circle and bolt holes so the two can be mated together. From this flange, the piping system is started. Normally, the thickness and O.D.(Outside Diameter) of the flange increase as the pressure rating of the piping system increases.

The most important part of a flange is its face. Flange faces are machined to provide adequate surface contact area for a gasket.

TYPES OF FLANGE

Flange classifications are:

Raised-Face: The contact area is raised 0.0625 inches for classes 150 and 300. For classed above 300, the contact area is raised 0.25 inches.

Flat-Face: When bolting class 150 or 300 flanges to cast iron flanges, flat-face should be used.

Ring Type Joint: Normal use is with flanges in classes 400 and over but can be designed for lower classes if desired.

Flanges are designed specifically for classes 150, 300, 400, 600, 900, 1500 and 2500. Common types of flanges are high-hub weld neck, low-hub slip-on, lap joint, threaded, socket and blind.

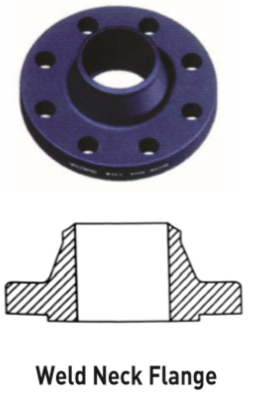

WELD NECK FLANGE

The weld neck flange is normally referred to as the high-hub flanges. It is designed to transfer and equally distribute stresses to the pipe, thereby reducing any concentration of high stress at the bottom of the flange after connections are made. The weld neck flange is the best-designed flange for butt welding because of its inherent strength. A long tapered hub and gradual transition of thickness in the region of the butt-weld joint adds reinforcement from the standpoint of strength and resistance to dishing. The smooth transition from the flange thickness to the pipe wall thickness effected by the taper is extremely beneficial under conditions of repeated bending caused by line expansion or other variable forces.

Weld neck flanges are used in serve services generally involving high pressure and sub-zero or high temperatures. Weld neck flanges are bored to match the I.D.(Inside Diameter) of the matching pipe. Therefore, the lighter(lower schedule) the pipe, the larger is the bore of the flanges.

The flange is bored to match the I.D. of the pipe after joining so no restriction inflow could increase stream turbulence and contribute to metal erosion.

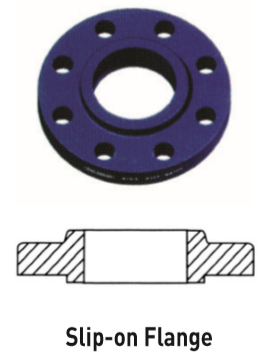

SLIP-ON FLANGE

A Slip-on flange has a low hub because the pipe slips into the flange prior to welding. It is welded both inside and out to provide sufficient strength and prevent leakage.

Slip-on flanges are all bored slightly larger than the O.D. of the matching pipe. Their lower cost makes them preferable to weld neck flanges to many users.

However, the installed cost is not much less than for a weld neck flange because of the additional welding involved.

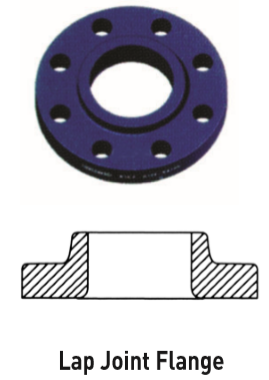

LAP JOINT FLANGE

The lap joint flange is almost identical to a slip-on flange except for the radius at the intersection of the bore and flange face. This radius is necessary to accommodate connection to a lap joint stub end.

.Normally, a lap joint flange and a lap joint stub end assembly are used mainly in piping systems that are frequently dismantled for inspection or cleaning.

These flanges are advantageous in systems where the ability to swivel flanges and align bolt holes simplifies the erection of large diameter and hard-to adjust piping.

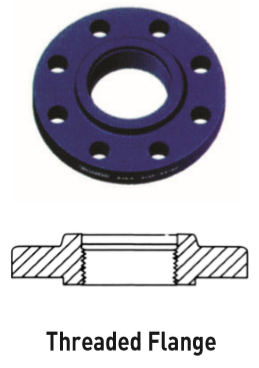

THREADED FLANGE

A threaded flange is similar to the slip-on flange, but the bore is threaded. Its chief merit is that it can be assembled without welding. This feature makes it preferable for services operating at low pressures and ambient temperatures. Threaded flanges can be installed in highly dangerous areas where welding might be hazardous.

Threaded flanges are unsuited for extreme temperature conditions or bending stresses of any great magnitude.

Widely fluctuating conditions could cause leakage through the threads after only a few cycle of heating or repeated exposure to stresses. Seal welding around the joint is sometimes performed to overcome the possibility of leakage, but this is not always satisfactory, nor possible.

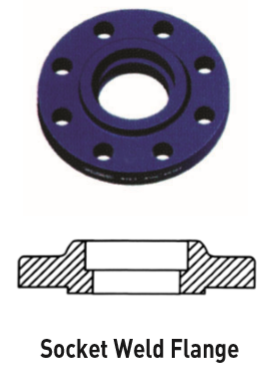

SOCKET WELD FLANGE

Socket weld flanges were initially developed for use in small-size high-pressure piping and slightly more expensive than the slip-on.

When provided with an internal weld, their static strength is equal to, but their fatigue strength is much greater than double-welded slip-on flanges.

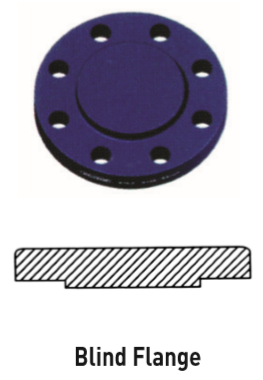

BLIND FLANGE

The blind flange is a solid forging used to blank off the end of a piping system and for gaining access to the interior of the line. These flanges from the stance of internal pressure and bolt load are the most highly stressed type of all. However, since the maximum stresses in a blind flange are bending stresses at the center, they can safely be permitted to be higher than in other types of flanges. However, they are not apt for repeated severe water hammer or when the temperature is a critical factor.

For these situations, a welding cap is better suited.